CALIPER - DDL

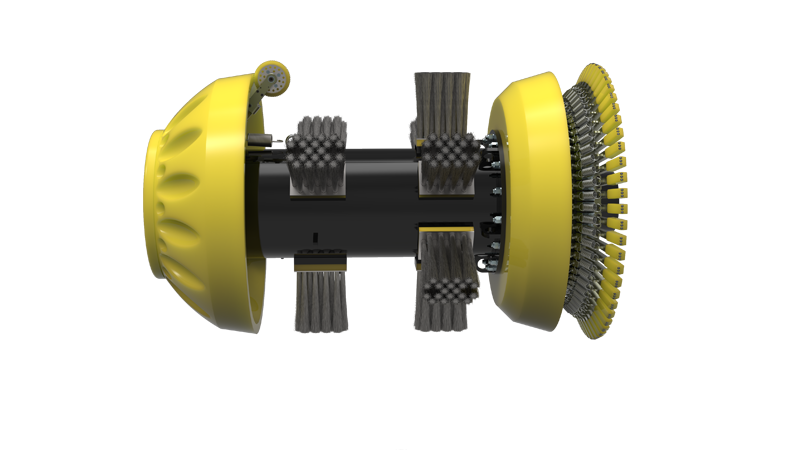

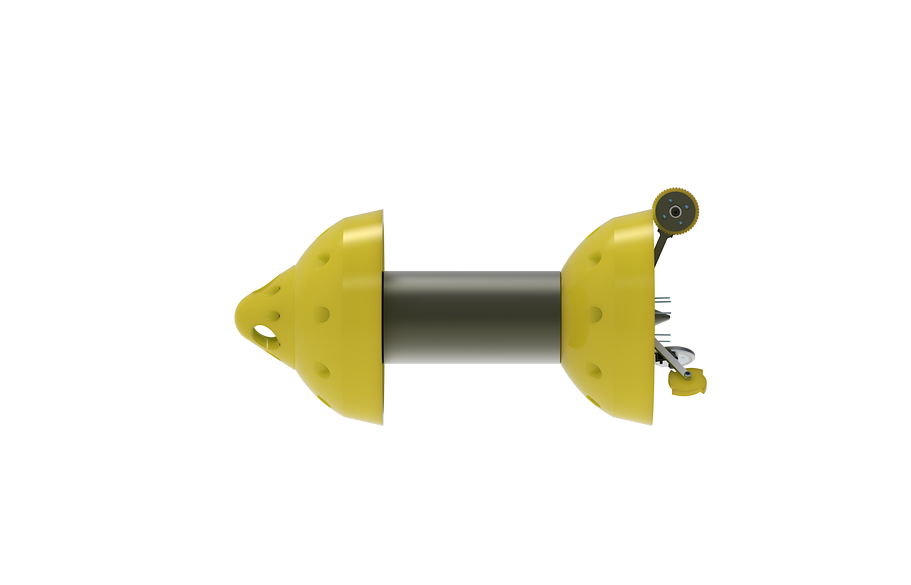

The DDL-DW2

The DdL DW2™ isn’t just about navigation—it’s a next-generation caliper tool designed to give operators precise data on the condition of their pipeline. Using advanced sensors and a high-resolution measurement system, the DW2 detects:

- Dents – Identifying deformations that could compromise future ILI runs.

- Wrinkles & Buckles – Spotting strain-related features before they become failures.

- Ovality – Measuring out-of-round conditions that affect flow and tool performance.

- Movement & Strain – Recording shifts that may impact long-term integrity.

This data is critical for integrity teams preparing lines for inspection or evaluating changes in their pipeline system.

Integrated IMU & GIS

Beyond caliper data, the DdL DW2 is equipped with advanced IMU navigation and GIS integration tools. This means operators receive not only precise measurements of pipeline geometry but also:

- Accurate mapping & GPS-referenced features

- Class location & MCA/HCA determinations

- Overland spill analysis for liquids

- Spatial deliverables for seamless GIS integration

The Advantage of DW2

With regulatory pressures increasing under CFR 192, 195, and the Mega Rule, operators need more than raw measurements—they need actionable insights. The DW2 combines high-resolution caliper data with geospatial intelligence to deliver complete reporting for your integrity management program.

Not Your Average Geometry Tool

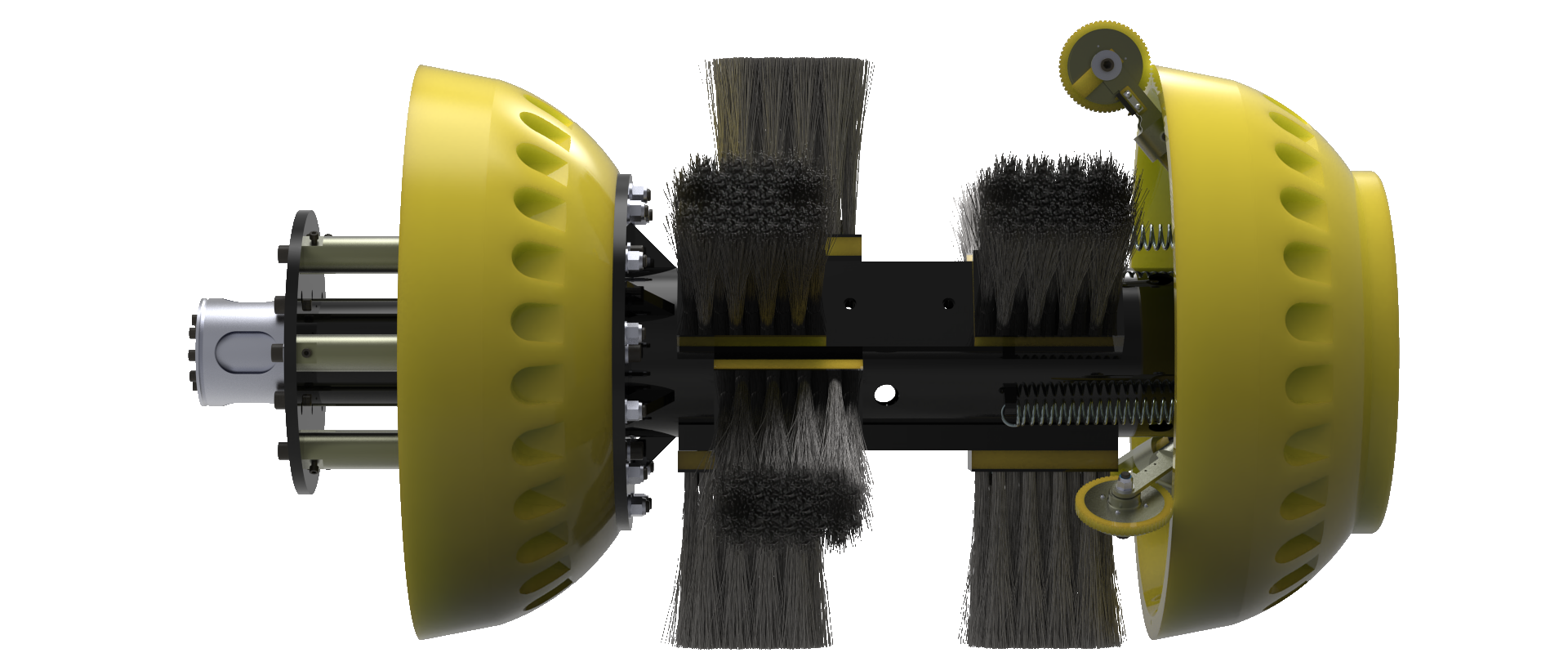

The Enduro Digitel Data Logger (DdL) offers both radius point readings and diametrical cross-sectional analysis; multiple channels are provided offering the ability to log pipeline anomalies in clock orientation. The gyro inputs provide the ability to determine bend radii and bend direction. GPS available for every Pipeline Line Listing Event.

For pipeline operators managing shorter segments (10 miles or less), Enduro’s Techless Caliper is the efficient solution you’ve been waiting for.

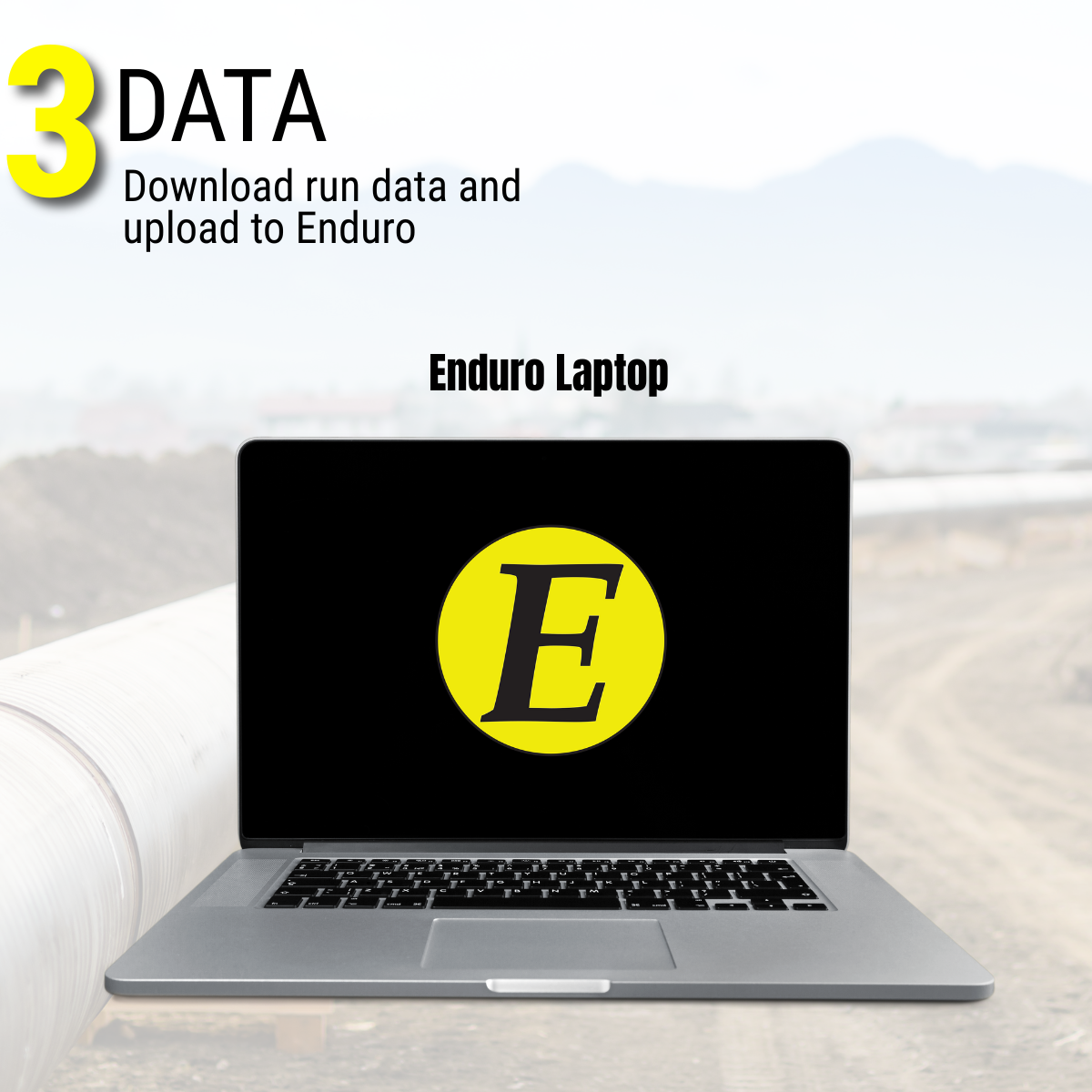

Designed specifically for ease of use, this tool eliminates the need for an on-site Enduro Field Technician—saving you time, cost, and coordination. With just three simple steps outlined in our Quick Start Guide (included with every tool), operators can confidently run a caliper inspection and gather results—fast.

THE DdL ADVANTAGE

- High resolution sensors

- 0.100 inch (2.54 mm) axial resolution

- 100% true circumferential coverage

- Precise buckle and wrinkle measurement

- No technician required – perfect for short-run pipelines

- Fast deployment – only 3 easy steps in the included guide

- Quick results – inspect and review data faster than ever

- Reliable insights – designed to detect dents, deformations, and geometric anomalies

Our Techless Caliper is easy as 1-2-3

A Supporting Cast – AGM II

The Above Ground Marker (AGM) is available for all DdL surveys. Enduro’s traditional AGM equipment provides a reference location at specific points along the pipeline. These locations are logged directly to the DdL for future reference and location assistance.

XYZ Mapping & Everything In-Between

Global Positioning System (GPS) equipment works well with the DdL. Excavations may be determined from logged GPS readings and given in GPS excavation points.

With the use of twin gyros in the DdL, profiling and mapping of the pipeline is possible, as direction and angle readings are made on all bends. Bends are easily seen and may be used as reference locations when locating anomalies. Enduro’s DdL equipment is capable of traversing and recording bend radii of 1.5 times pipe diameter. (Bends of 1 diameter have been logged with special tool adaptation.)

*The AGM model shown is currently only available for the DfL tool. Coming soon for the DdL.

Ready to get a quote?

HAVE QUESTIONS ABOUT YOUR DDL PROJECT? CONTACT OUR OPS TEAM

Frequently Asked Questions

What is the DdL Caliper Tool?

The DdL Caliper is Enduro’s “techless” geometry inspection tool. It uses high-resolution caliper sensors and odometers to measure dents, ovality, wrinkles, and other deformation in the pipe wall without relying on complex on-board electronics.

What pipeline conditions can the DdL Caliper detect?

The DdL Caliper is designed to identify and size features such as dents, ovality, wrinkles, buckle indications, and areas of bending strain. This helps operators verify pipe shape, assess integrity threats, and prepare lines for ILI metal-loss inspections.

When should I run a DdL Caliper inspection?

Operators typically run the DdL Caliper before or between ILI metal-loss runs to confirm geometry, check for construction damage, verify new lines, or investigate suspected deformation. It is especially useful in lines with known dents, fittings, or complex construction histories.

How do I schedule a DdL Caliper inspection or request pricing?

You can contact Enduro directly by phone or email, or submit a request through the website’s contact/inspection form. An Enduro representative will review your line details, recommend an inspection plan, and provide a proposal.

What is the "techless" caliper?

Designed specifically for ease of use, this tool eliminates the need for an on-site Enduro Field Technician—saving you time, cost, and coordination. With just three simple steps outlined in our Quick Start Guide (included with every tool), operators can confidently run a caliper inspection and gather results—fast.