Ensuring Pipeline Integrity Starts with Proper Cleaning

Choosing the Right Pig for the Job.

This article was written by J.R. Morgan, Director of Pipeline Cleaning and Maintenance at Enduro, with over 30 years in pipeline industry.

With over 30 years of experience in pipeline operations, I’ve seen firsthand how essential proper cleaning is to pipeline integrity. Whether you're transporting crude oil, refined products, or gas, a proactive pigging program isn’t just recommended—it’s foundational.

At Enduro, I work closely with operators facing complex cleaning challenges. When the job gets tough, I help customers select the right solution for their system's debris, configuration, and operational demands.

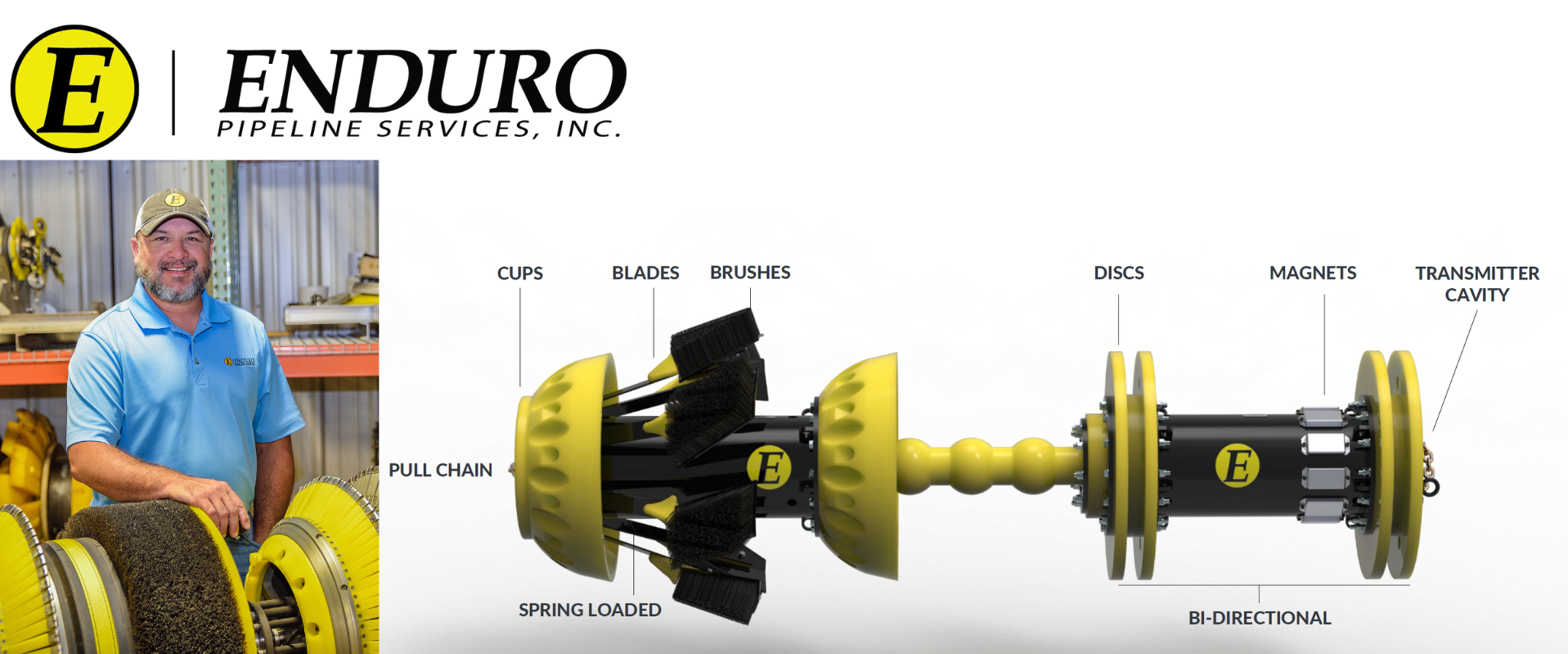

Choosing the Right Pig for the Job. In the above photos we’ve shared, you’ll see examples of heavy ferrous debris—material that can severely compromise flow efficiency and inspection quality.

To address this type of contamination, I typically recommend:

- Rare-earth magnet-equipped pigs to attract ferrous material

- Multiple runs to account for magnet saturation

- Combination pigs with cups and discs for both scraping and sweeping

- Increased pig weight for enhanced scraping force

- Additional cleaning elements (extra cups, discs, or brushes)

- Multi-section pig trains for heavily contaminated lines

Maintaining a consistent speed of 2–5 MPH is critical. Pigs should be run until debris levels significantly taper off and magnets indicate minimal remaining material.

Establishing a Cleaning Schedule. A successful pigging program starts with establishing a clean baseline. Once debris levels are reduced, set a routine cleaning frequency.

If quarterly runs still retrieve large volumes of debris, it's a clear indicator that your schedule needs adjustment. Regular cleaning minimizes risk, supports efficient operation, and ensures your system is always ready for inline inspection (ILI).

Clean Before You Inspect. Ferrous debris can have a direct, negative impact on ILI tool performance, causing: • Sensor lift-off • Odometer wheel inaccuracies • Magnet section saturation.

These issues lead to poor data, failed inspections, and costly reruns. Cleaning prior to ILI isn’t optional—it’s an operational requirement.

Pipeline integrity doesn’t start with inspection. It starts with cleaning.

If you're unsure which cleaning pig is best suited for your system, our team is ready to assist you. I invite you to discuss your project needs with us, whether through a phone call, email, or by visiting our headquarters in Tulsa. During your visit, you'll have the chance to tour our manufacturing facility, learn more about our products and services, and work with our experts to create a customized cleaning solution tailored to your specific project.

To schedule a consultation, reach out to our team today. We’re here to support your operations—every step of the way.

J.R. Morgan: jrm@enduropls.com | Toll free 800-752-1628 | Office 918-446-1934 | Cell 918-557-5067

“Learn more about Enduro’s

cleaning pigs