FOAM Cleaning Pigs

Enduro’s Foam Pigs are available in a wide variety of sizes and configurations, making them a versatile choice for numerous pipeline applications.

Key Features

- Wide Size Range: Offered in diameters from 2" to 60", making them suitable for everything from small laterals to large transmission lines.

- Multiple Density Options: Available in light, medium, and heavy-density foam, allowing operators to match pig aggressiveness and durability to their application.

- Configurable Designs: Can be supplied as bare, criss-cross coated, silicon carbide grain coated, scrub, brush, or swab-style pigs to support a variety of cleaning objectives.

- Custom Features: Pigs can be manufactured with transmitter cavities, ropes, and tow cables to support tracking, retrieval, and specialized operations.

- Cost-Effective Performance: Foam pigs offer an economical option for frequent pigging programs or applications where a disposable tool is ideal

Size Range : 2” to 60”

(Custom options available for unique applications.)

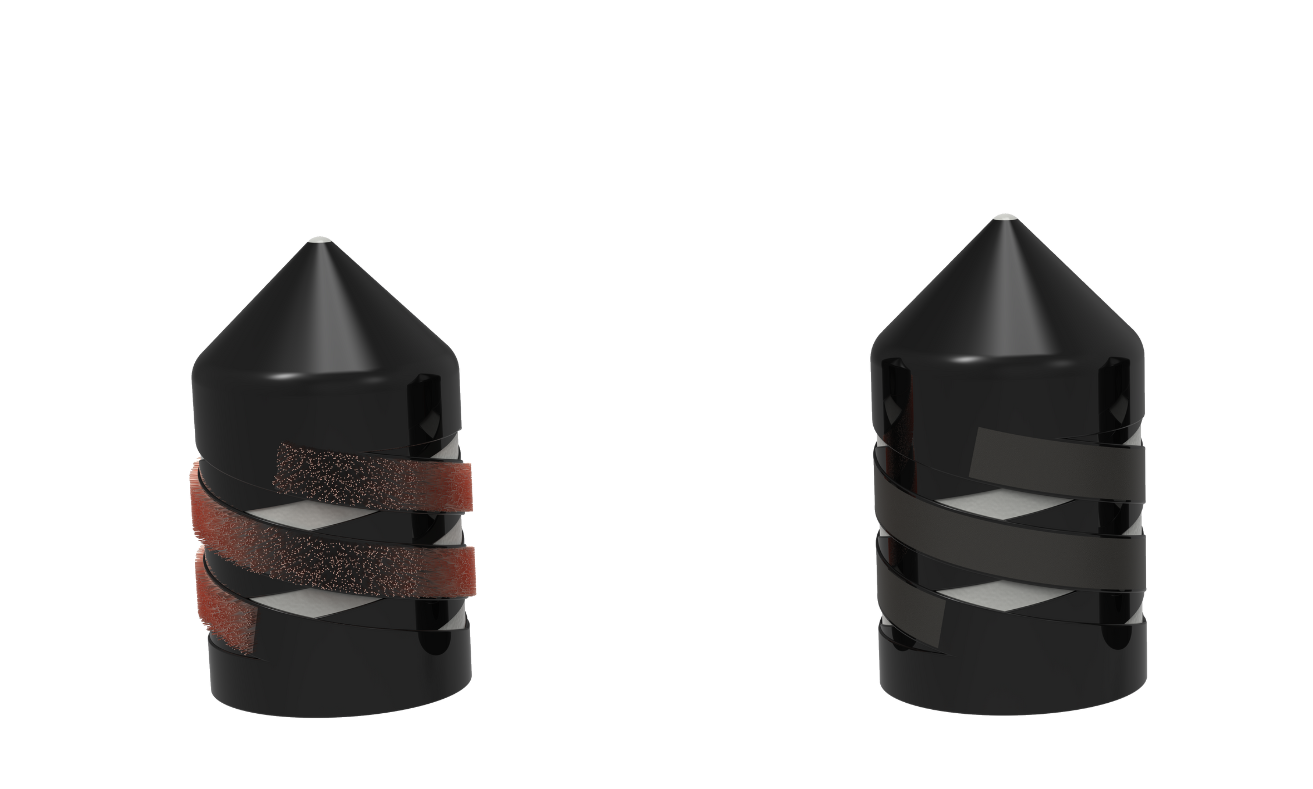

Silicon Carbide Grain Scrub Brush

Criss-Cross Coated Bare Swab

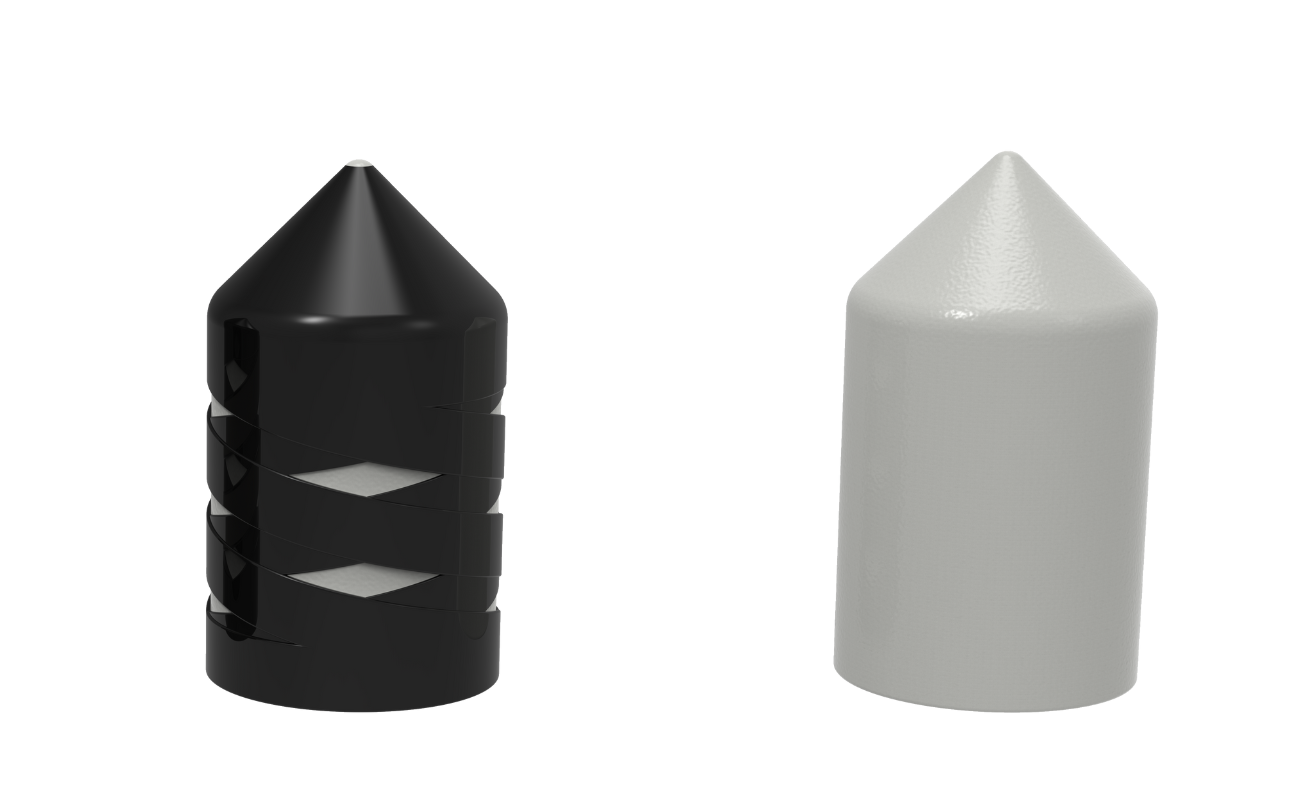

Foam Pig Configurations

Enduro Foam Pigs can be built in configurations such as:

- Bare foam – for light cleaning, displacement, and swabbing

- Criss-cross coated – for enhanced wiping and debris removal

- Abrasive coated (e.g., silicon carbide grain) – for more aggressive cleaning and scale removal

- Scrub or brush-enhanced designs – for increased contact and friction along the pipe wall

- Swab pigs – for drying and light cleaning after hydrotesting or chemical runs

Applications:

Foam pigs are an excellent choice for:

- Routine pipeline cleaning and maintenance

- Batching and product separation

- Dewatering and drying after hydrotests

- Displacement and purging operations

- Cleaning plastic pipelines where steel-bodied pigs may not be suitable

- Situations where a

lightweight or disposable pig is preferred.

Why Operators Choose Foam Pigs

- Broad size and density range

- Configurable to match your cleaning goals

- Backed by Enduro’s in-house urethane expertise

- Supported by a team that can help you design complete cleaning programs, not just individual pigs

- Designed, manufactured, and supported by a company focused on pipeline cleaning, tracking, and integrity

Request a Quote

For sizing, configuration recommendations, or custom builds: 800-752-1628

jrm@enduropls.com, or submit a

quick quote request online.

Browse all cleaning pigs

FAQs

What foam density should I choose?

Light-density foam pigs are typically used for swabbing, dewatering, and light cleaning. Medium and heavy-density pigs are used for more demanding cleaning runs or when more abrasion resistance is required

Can foam pigs be tracked?

Yes. Foam pigs can be manufactured with transmitter cavities, allowing you to install Enduro transmitters and track the pig using your geophones or receivers.

Are foam pigs suitable for plastic pipelines

Yes. Foam pigs are well-suited for plastic pipelines where steel-bodied pigs might be too aggressive or difficult to navigate.