Buried in Crud: The Real Cost of Skipping Proper Cleaning

Would You Still Run That ILI Tool If You Knew What Was Waiting in the Receiver?

We’ve all seen the photos — ILI tools coming back completely buried in gunk. Thick, sticky, caked-on debris. And every time I see one, I can’t help but ask myself:

If the operator knew the tool would come out looking like this... would they have run it in the first place?

Here’s one of those photos from a crude line that hadn’t been cleaned properly before the inspection. Take a close look at the MFL detection section — specifically the sensor assembly just above the yellow moment arms. Those shiny little tabs are designed to stay in direct contact with the pipe wall. Any lift-off from debris? Your data’s already compromised.

These tools rely on clean, consistent background magnetization to calculate accurate metal loss readings. If debris is keeping the sensors off the wall, not only is your baseline wrong, but the peak values of leakage (the whole point of the run) are skewed too. Bottom line: you’re not getting the data you need.

So, what’s the fix?

In line conditions like this, a few foam pigs or basic brushes just aren’t going to cut it. Odds are, you’ve got hard wax or paraffin bonded to the pipe wall. Sure, you can try brushing — but in this environment, those brushes will pack up fast and quit doing their job halfway down the line.

You need more.

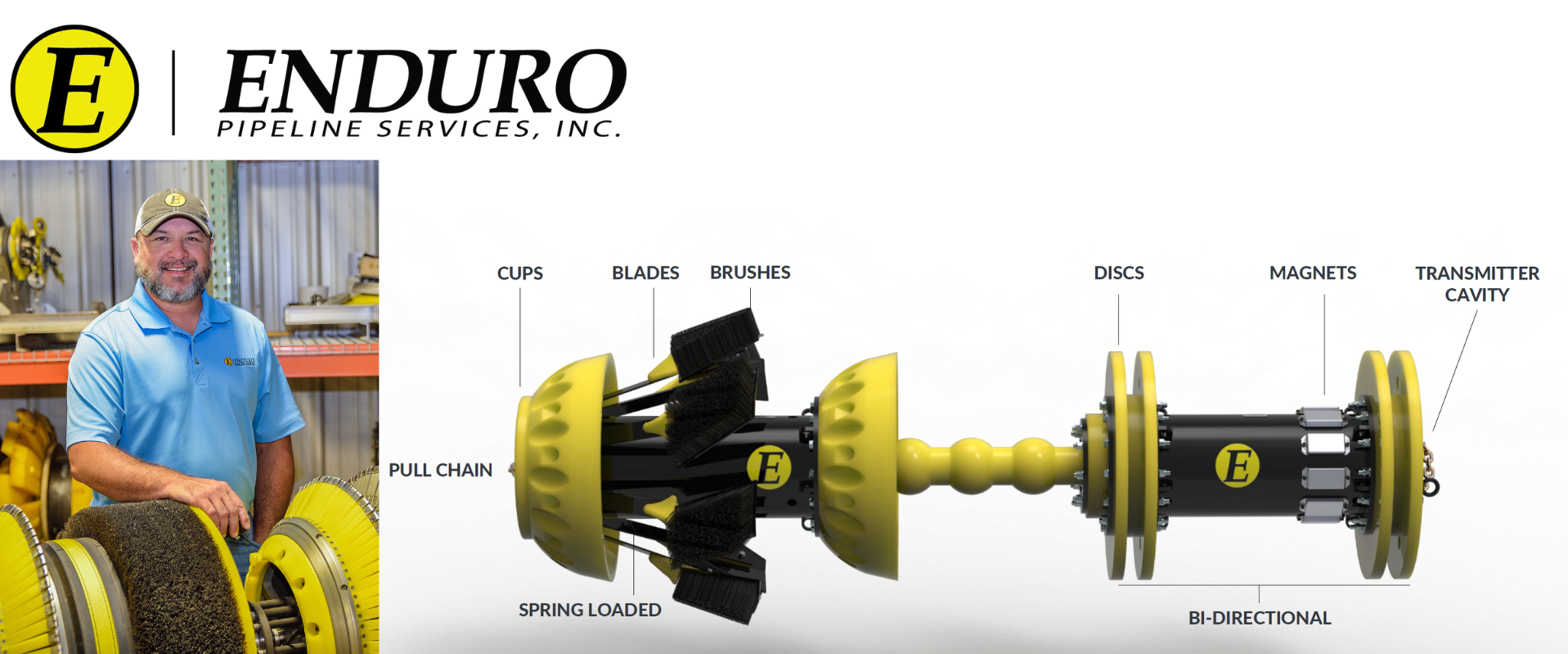

We’re talking chemical cleaning, combined with the right tools. Heavy-duty cleaning pigs. Tandem-section tools that bring weight, muscle, and more cleaning surface to the fight. And even then, don’t send them in first. You’ve got to pig in stages, building up with each run. Otherwise, your receiver’s going to be overwhelmed by the sheer volume of debris.

In some cases, xylene flushes are an excellent option to break up wax and allow cleaning tools to work more effectively. Just don’t waste your time on foam pigs in a mess like this — they won’t make a dent.

If it’s your name on the ILI schedule and you’re prepping a crude line that hasn’t seen proper maintenance, do yourself a favor: talk to your service provider before the run.

This is exactly what we deal with at Enduro, day in and day out. From chemical cleaning strategies to tool selection, we help operators get these lines ready — because if the cleaning isn’t done right, the ILI team can’t do their job. It’s a hand-in-glove operation.

Get it done right the first time, and everybody wins.

— Have questions about cleaning before your next ILI run? Give us a call at 800-752-1628, visit our website at www.enduropls.com or get started with a quote at www.enduropls.com/quick-quotepage. We’re here to help.