The Evolution of Pipeline Pigs

From Squeals to Smart Tech: The Evolution of Pipeline Pigs

If you’ve ever wondered why a high-tech pipeline tool carries the humble name “pig,” the answer takes us back more than a century—when pipeline cleaning was loud, messy, and surprisingly inventive.

The Squealing Origin

The earliest “pigs” were nothing like today’s precision-engineered tools. Pipeline operators stuffed straw bales or leather bundles wrapped in barbed wire or metal discs into their lines to scrape away wax, rust, and other buildup. As these makeshift devices rattled along, friction against the pipe wall created a piercing squeal. Crews said it sounded like a pig in distress—and the name stuck.

From Crude Cleaners to Engineered Solutions

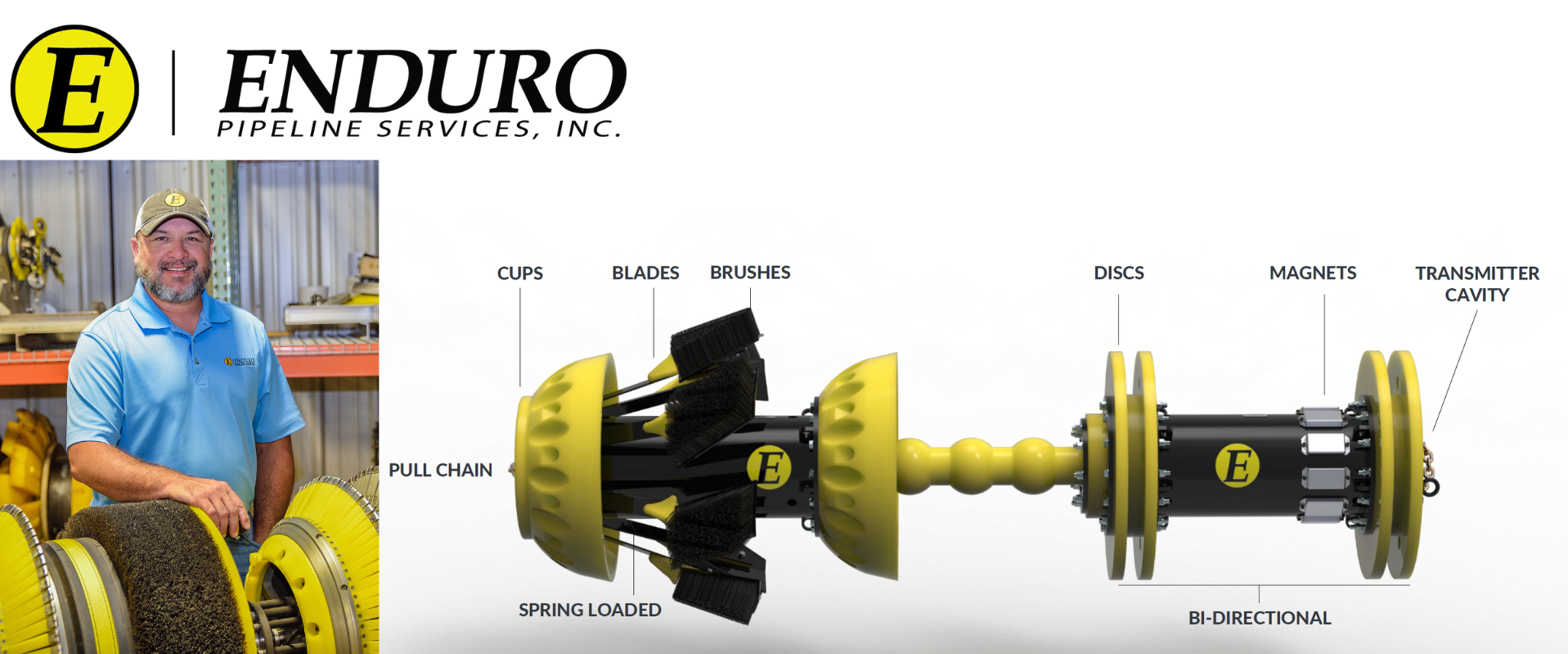

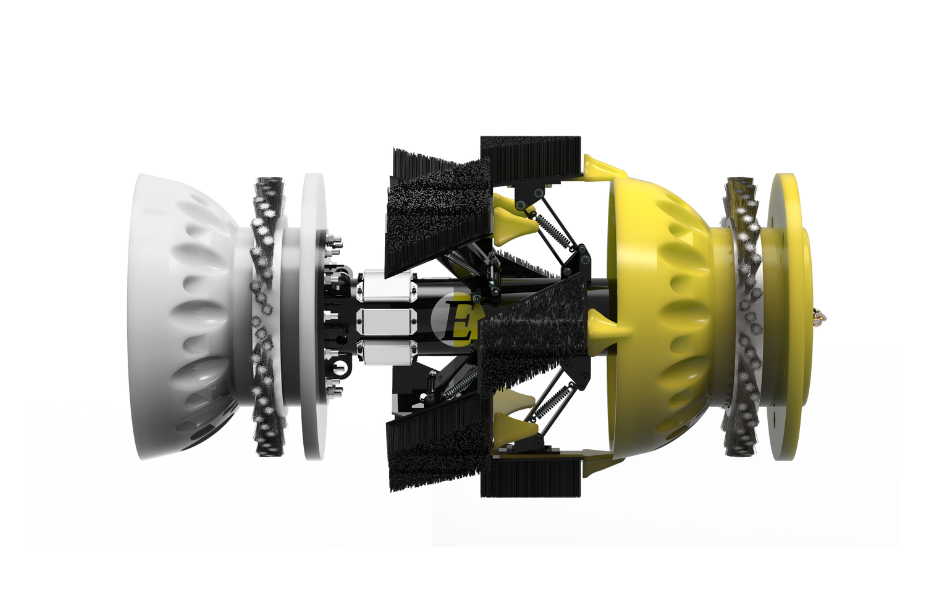

Over time, operators refined these tools into purpose-built cleaning pigs. Instead of straw and wire, urethane cups and discs became standard, providing better sealing and consistent cleaning action. Enduro has carried that spirit of innovation forward with a full line of urethane and specialty cleaning pigs designed to tackle everything from heavy black powder to stubborn scale in pipelines from 2" to 60".

- Cup Pigs and Disc Pigs: Reliable, economical options for routine debris removal.

- Wire-Brush and Magnetic Pigs: Ideal for rust, mill scale, or black powder.

- Custom Builds: Enduro engineers design pigs to match unique diameter changes, bends, or pressure conditions—because no two pipelines are alike.

The Rise of “Smart Pigs”

Cleaning eventually paved the way for inspection. Operators began adding sensors and electronics to record pipeline conditions as the pig traveled. These “intelligent” or “smart pigs” now map corrosion, measure wall thickness, and detect tiny cracks—all without shutting down the line.

Enduro supports this next step too. A clean line is critical before any in-line inspection (ILI) run, and our cleaning pig programs prepare pipelines for the most accurate smart-pig data—saving time, money, and potential re-runs.

Why Cleaning Still Matters

Even in the age of sophisticated ILI tools, effective cleaning is the foundation of pipeline integrity. Residue or liquids left behind can compromise sensor readings and create costly delays. That’s why Enduro’s Cleaning Division offers:

- Expert Consultation: We evaluate every line’s history, product, and operating pressure to recommend the right pig and cleaning sequence.

- Quick Turnaround: Most standard pigs ship same day, and custom orders are fast-tracked from our Tulsa, Oklahoma manufacturing facility.

- Proven Reliability: Backed by decades of field success and a 96% “extremely satisfied” customer rating.

Keep Your Pipeline Running at Its Best

From the squeal of straw bales to the quiet efficiency of today’s smart technology, pipeline pigs have come a long way. Yet the core mission remains the same: keep product moving safely and efficiently.

Whether you need a simple urethane cup pig or a complete pre-ILI cleaning program,

Enduro Pipeline Services is here to help.

Request a Quick Quote or explore our

full line of cleaning pigs to find the

right tool for your line.