Choosing the Right Cleaning Pig: A Pipeline Operator’s Perspective

Custom Pipeline Cleaning Pigs and Programs Designed for Your Line

This article was written by Chris Escoe, Senior Product & Technical Specialist at Enduro, with over 20 years in pipeline pigging and cleaning.

After more than 29 years in the pipeline industry, I’ve learned one simple truth: no two pipelines arealike, and no two cleaning programs should be either. Every operator wants the same thing — reliable performance, fewer surprises, and inspection runs that don’t fail because of debris or preparation issues. But the way you get there depends on your pipeline’s unique conditions.

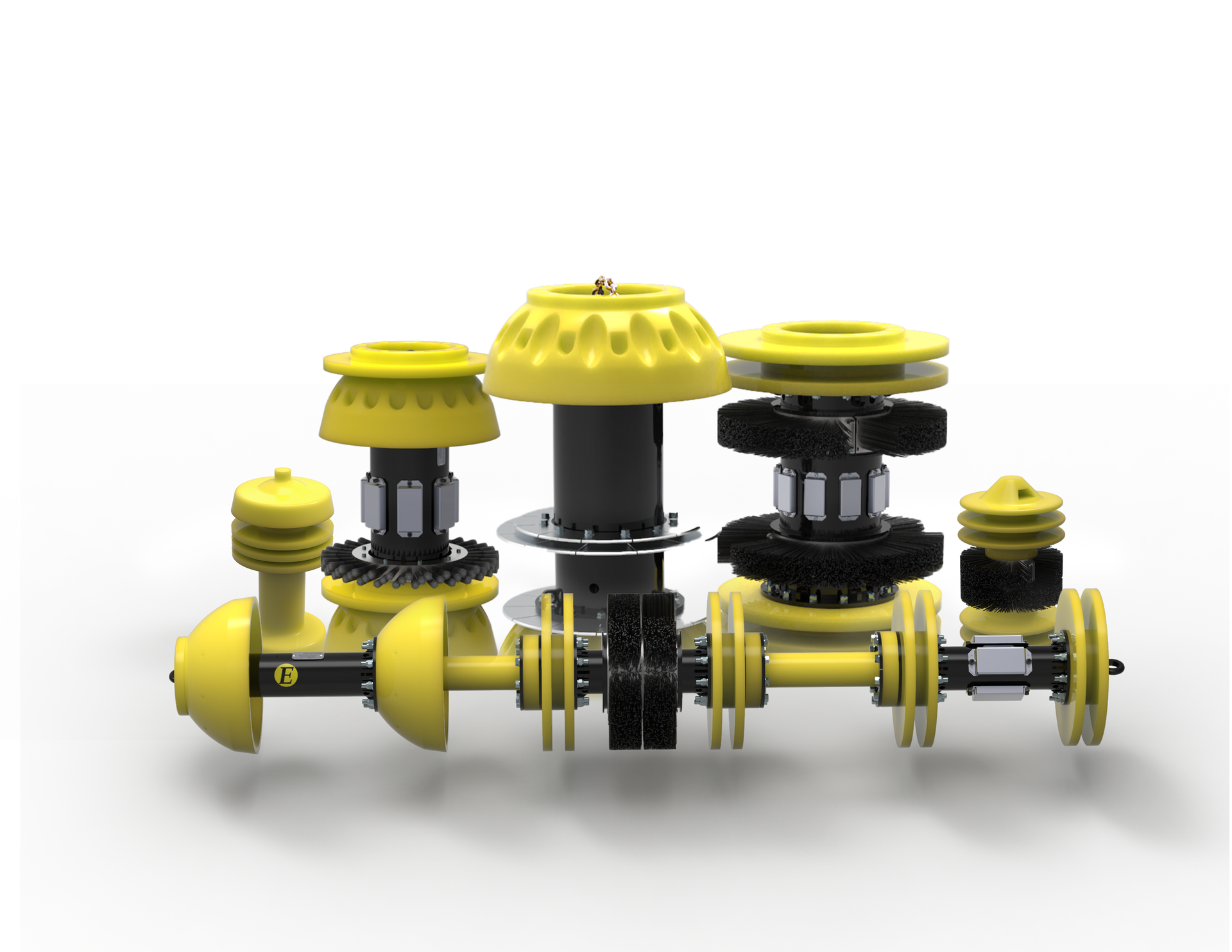

That’s why at Enduro, we don’t just build cleaning pigs. We work with operators to design custom cleaning solutions that match the pipeline, the debris load, and the long-term goals for integrity management.

Start With the Pipeline, Not the Pig

When operators ask me what cleaning pig they should run, my first question back is simple: what’s in your line?

- Is it paraffin, scale, black powder, or mixed debris?

- Are you preparing for in-line inspection, or just keeping flow efficient?

- What kind of bends, valves, and diameter changes do we need to plan for?

The answers shape everything that follows. A brush pig can scrape deposits that a foam pig would glide past, while a magnet pig will pick up ferrous debris that brushes won’t touch. Sometimes you run them together, other times separately — it all depends on the cleaning objective.

Custom Configurations That Work

I’ve spent my career designing custom cleaning plans because operators can’t afford cookie-cutter answers. Maybe your pig needs six discs for control, or maybe it needs added brush and magnet assemblies for a tough debris load. Maybe a bi-directional design makes sense for your system, or maybe it doesn’t. The goal is always the same: a pig that’s built for your pipeline, not just for the catalog.

That’s the advantage of Enduro’s Pipeline Cleaning Pig Division. We’ve got a team with more than 80 years of combined cleaning experience, and we thrive on tackling the toughest challenges operators face.

Why I Love This Work

For me, pipeline pigging isn’t just about tools — it’s about teamwork. I’ve built strong friendships in this industry, and I value every chance to speak with an operator, talk through their challenges, and help find a solution.

My background as a former athlete taught me that persistence and preparation are just as important as performance. That’s how I approach every project: plan hard, work hard, and keep the customer first.

As I like to say:

“The will to prepare to win is just as important as the will to win.”

Let’s Talk About Your Line

If you’re facing a tough cleaning challenge, you don’t have to figure it out alone. Our Cleaning Pig Division is here to help you design the right configuration, get tools delivered on time, and keep your operation moving.

Chris Escoe

Senior Product and Technical Specialist

every day, we give it our best- to the tools We build

to the services we deliver

Toll free

800-752-1628 |

Office

918-446-1934

Cell

918-557-5188

chrise@enduropls.comchrise@enduropls.com